Die Casting: The Art of Precision Manufacturing

Die casting, a cornerstone of modern manufacturing, is a versatile and efficient process that has revolutionized industries worldwide. From automotive components to electronic devices, die casting plays an integral role in producing durable, high-quality products with exceptional precision. In this article, we’ll explore the fundamentals of die casting, its process, benefits, and its applications across various industries.

What is Die Casting?

Die casting is a metal fabrication process where molten metal is injected under high pressure into a steel mold, or die, to create intricate and detailed components. These molds are reusable and capable of producing thousands of identical parts with consistent quality. The process is especially popular for creating lightweight and robust parts with tight tolerances and smooth finishes.

Common materials used in die casting include aluminum, zinc, magnesium, and their alloys. Each material brings unique properties, making die casting suitable for a wide range of applications.

The Die Casting Process

1. Mold Preparation

The die casting process begins with preparing the mold. A steel mold, consisting of two halves (the cover die and the ejector die), is designed and fabricated to fit the desired product’s specifications. The mold is cleaned and coated with a lubricant to facilitate easy ejection of the finished part and to prevent wear and tear.

2. Melting the Metal

The chosen metal or alloy is melted in a furnace until it reaches the desired temperature. Precision in temperature control is crucial, as it affects the flowability and quality of the molten metal.

3. Injection

The molten metal is injected into the mold cavity at high pressure using a specialized machine. The high pressure ensures that the metal fills every crevice of the mold, capturing intricate details and producing a uniform component.

4. Cooling

Once the mold is filled, the metal is left to cool and solidify. Cooling time varies depending on the metal used and the complexity of the mold. Proper cooling ensures dimensional stability and reduces the risk of defects.

5. Ejection

After solidification, the mold is opened, and the finished part is ejected using ejector pins. The part undergoes inspection to ensure it meets quality standards. Any excess material, known as flash, is trimmed away.

6. Finishing

The final step involves additional finishing processes, such as machining, polishing, coating, or painting, to enhance the product’s appearance and functionality.

Types of Die Casting

Die casting processes can be categorized into two main types, each suited for specific applications:

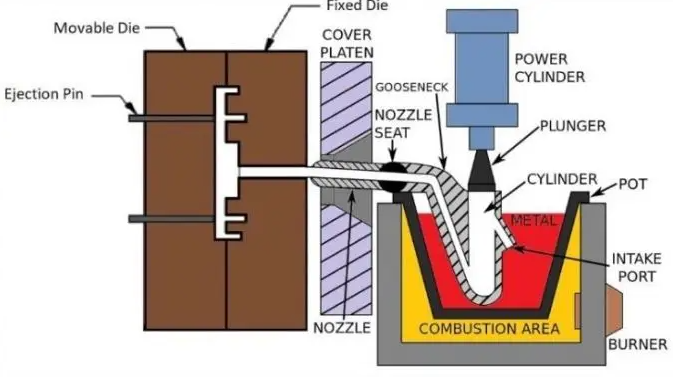

1. Hot-Chamber Die Casting

This method is commonly used for metals with lower melting points, such as zinc and magnesium. In hot-chamber die casting, the injection mechanism is submerged in the molten metal, allowing for quick and efficient casting. This process is ideal for high-volume production.

2. Cold-Chamber Die Casting

Cold-chamber die casting is used for metals with higher melting points, such as aluminum and copper alloys. In this process, the molten metal is poured into a chamber separate from the injection system. While it requires more time compared to hot-chamber casting, it can handle materials that require higher temperatures.

Benefits of Die Casting

Die casting offers several advantages that make it a preferred manufacturing method:

1. Precision and Accuracy

Die casting produces components with exceptional dimensional accuracy and intricate details, reducing the need for secondary machining processes.

2. High Production Efficiency

Once the mold is prepared, the die casting process is rapid, enabling the production of large volumes of parts in a short time.

3. Versatility

Die casting accommodates various metals and alloys, providing flexibility for diverse applications.

4. Cost-Effectiveness

Despite high initial tooling costs, die casting becomes cost-effective in high-volume production due to its efficiency and minimal waste.

5. Strength and Durability

Die-cast components are known for their strength and durability, making them suitable for demanding applications.

6. Aesthetic Appeal

The process produces parts with smooth surfaces, which can be easily finished or coated to enhance visual appeal.

Applications of Die Casting

Die casting’s versatility makes it indispensable across numerous industries. Here are some key applications:

1. Automotive Industry

Die casting is extensively used to manufacture components like engine blocks, transmission housings, and wheels. Its ability to create lightweight yet durable parts contributes to improved fuel efficiency and vehicle performance.

2. Electronics

The electronics industry relies on die casting for components like heat sinks, connectors, and enclosures. The process ensures precision and heat dissipation, essential for electronic devices.

3. Consumer Goods

Die casting is employed in producing everyday items such as kitchen appliances, furniture fittings, and hand tools. It provides the necessary strength and aesthetic quality for these products.

4. Aerospace

In the aerospace sector, die casting produces lightweight and reliable components that meet stringent quality standards. These include structural parts, brackets, and housings for avionics.

5. Medical Devices

Die casting is also integral to the medical field, where precision and hygiene are paramount. Applications include surgical instruments, diagnostic equipment, and implantable devices.

Challenges in Die Casting

Despite its numerous benefits, die casting has some challenges:

1. High Initial Costs

The cost of designing and manufacturing molds can be significant, making it less viable for low-volume production.

2. Limited Material Choices

Not all metals are suitable for die casting, limiting its application in some industries.

3. Defects

Improper process control can lead to defects such as porosity, warping, or incomplete filling of the mold. However, advancements in technology and quality control have mitigated many of these issues.

The Future of Die Casting

As industries continue to evolve, die casting is poised for significant advancements. Innovations in materials, such as high-strength alloys and composites, are expanding its capabilities. Automation and AI-driven quality control systems are enhancing precision and reducing defects. Additionally, the push for sustainable manufacturing has led to the development of energy-efficient die casting machines and recyclable materials.

Conclusion

Die casting stands as a testament to the ingenuity and precision of modern manufacturing. Its ability to produce complex, durable, and high-quality components has made it indispensable across industries. While challenges exist, ongoing advancements ensure that die casting will remain a vital process in shaping the future of manufacturing.

Whether it’s the sleek design of a smartphone or the sturdy frame of a car, die casting is the silent hero behind countless products that define our daily lives. As technology progresses, the potential of die casting will only grow, solidifying its place at the forefront of industrial innovation.